Automated Inventory Management: Transforms Supply Chain Efficiency for Growing Businesses

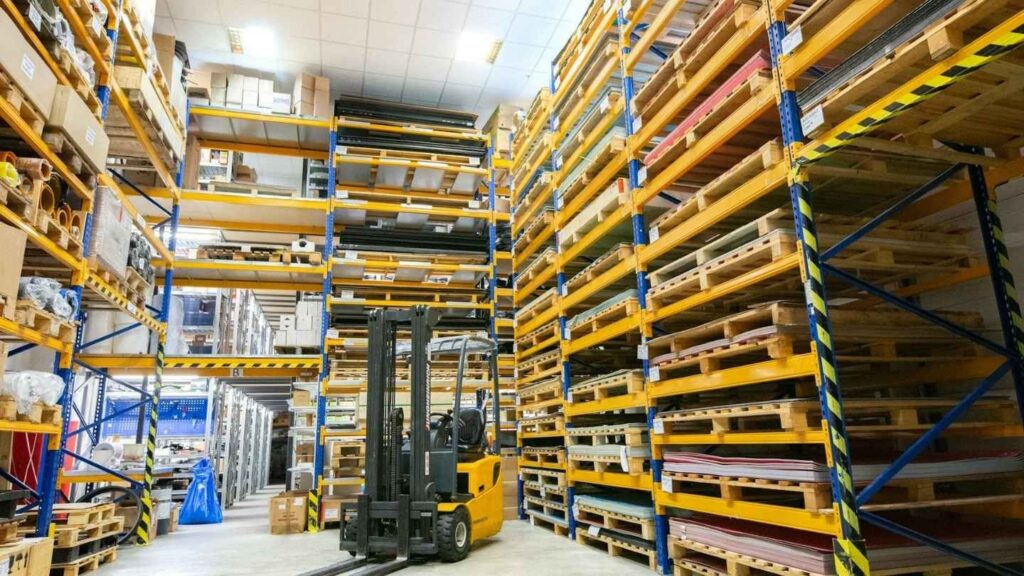

Automated inventory management has become the backbone of modern supply chain operations, and I’ve witnessed firsthand how it revolutionizes business growth. After years of helping companies streamline their warehouse operations, I can confidently say that manual stock tracking simply cannot keep pace with today’s market demands.

This comprehensive guide explores how automation technology reshapes inventory control, reduces human error, and drives operational excellence. You’ll discover practical strategies for implementing smart inventory systems, understand real-time stock tracking benefits, and learn why demand forecasting software has become essential. Whether you’re managing a small warehouse or scaling enterprise operations, this article provides actionable insights into inventory optimization, supply chain automation, and stock management solutions that deliver measurable results.

Understanding the Foundation of Modern Stock Control

The landscape of warehouse management has shifted dramatically over the past decade. Traditional spreadsheet tracking and periodic manual counts have given way to sophisticated systems that monitor every product movement in real time. Companies that once relied on clipboards and guesswork now leverage powerful technology to maintain complete visibility over their entire inventory ecosystem.

Automated inventory management refers to technology-driven solutions that track, organize, and optimize stock levels without constant human intervention. These systems integrate barcode scanning, RFID technology, and cloud-based software to create seamless inventory visibility across multiple locations. The result is a streamlined operation where data flows continuously between warehouses, retail locations, and online platforms.

Why Businesses Are Making the Switch

Growing companies face increasing pressure to fulfill orders faster while maintaining accuracy. Manual processes create bottlenecks that slow operations and frustrate customers. Smart inventory solutions eliminate these pain points by providing instant access to stock data and automating routine tasks that previously consumed valuable employee hours.

The shift toward automation isn’t merely about convenience. It represents a fundamental change in how businesses approach supply chain efficiency and resource allocation. Organizations implementing these systems report significant improvements in order accuracy, reduced carrying costs, and enhanced customer satisfaction rates.

The Evolution of Warehouse Technology

Automated inventory management Inventory tracking has evolved from simple ledger books to sophisticated digital ecosystems. Early computerized systems in the 1980s introduced basic database functionality. The 1990s brought barcode technology mainstream. Today’s solutions incorporate artificial intelligence, machine learning, and predictive analytics to anticipate demand patterns before they emerge.

Key Features That Drive Operational Excellence

Automated inventory management Modern inventory systems offer capabilities that transform daily operations completely. Understanding these features helps businesses select solutions aligned with their specific needs and growth objectives.

Real-Time Stock Visibility

Knowing exactly what’s available at any moment prevents overselling and stockouts. Real-time tracking updates inventory counts automatically as products move through the supply chain. This visibility extends across all channels, ensuring consistent information whether customers shop online, in-store, or through mobile applications.

Warehouse managers gain immediate insight into product locations, quantity levels, and movement history. This transparency enables faster decision-making and reduces the time spent searching for misplaced items or reconciling discrepancies between physical counts and system records.

Intelligent Reorder Point Automation

Automated inventory management systems calculate optimal reorder points based on historical sales data, lead times, and seasonal fluctuations. When stock levels drop below predetermined thresholds, the system automatically generates purchase orders or alerts procurement teams to take action.

This proactive approach eliminates the guesswork from purchasing decisions. Businesses maintain adequate stock without tying up excessive capital in slow-moving products. The balance between availability and efficiency improves dramatically when algorithms handle these calculations continuously.

Demand Forecasting Capabilities

Automated inventory management Predicting future demand remains one of the most valuable features modern systems provide. Advanced algorithms analyze past sales patterns, market trends, promotional calendars, and external factors to project upcoming inventory needs with remarkable accuracy.

Accurate forecasting reduces both overstock situations and missed sales opportunities. Businesses can plan purchasing, staffing, and warehouse space requirements months in advance, creating smoother operations throughout peak seasons.

Benefits That Impact Your Bottom Line

Automated inventory management Implementing smart stock control delivers measurable advantages across multiple business areas. These benefits compound over time as systems learn patterns and optimize processes continuously.

- Reduced labor costs through elimination of manual counting and data entry tasks

- Lower carrying costs by maintaining optimal stock levels without excess inventory

- Improved cash flow through better purchasing timing and reduced dead stock

- Enhanced customer satisfaction with higher order accuracy and faster fulfillment

- Decreased shrinkage through better tracking and accountability measures

Operational Efficiency Gains

Time savings represent one of the most immediate benefits businesses experience. Tasks that previously required hours of manual effort now happen automatically in seconds. Employees redirect their energy toward strategic activities that drive growth rather than repetitive administrative work.

Error reduction accompanies these efficiency improvements. Human data entry mistakes disappear when systems capture information directly from barcodes and sensors. This accuracy improvement cascades throughout the organization, affecting everything from financial reporting to customer communications.

Challenges to Consider Before Implementation

Automated inventory management While the advantages are substantial, businesses should approach implementation with realistic expectations. Understanding potential obstacles helps organizations prepare adequately and avoid common pitfalls.

- Initial investment costs for software, hardware, and integration services

- Training requirements for staff members adapting to new workflows

- Data migration complexity when transitioning from legacy systems

- Integration challenges with existing accounting and sales platforms

- Change management resistance from employees comfortable with current processes

Overcoming Implementation Hurdles

Successful deployment requires careful planning and stakeholder buy-in. Starting with a pilot program in one warehouse or product category allows teams to learn the system before full-scale rollout. This phased approach reduces risk and builds confidence among employees who will use the technology daily.

Choosing vendors with strong support services makes the transition smoother. Look for providers offering comprehensive training programs, responsive technical assistance, and proven integration experience with your existing business systems.

How These Systems Transform Daily Operations

The practical impact of automated inventory management becomes evident in everyday warehouse activities. Receiving shipments, picking orders, conducting audits, and managing returns all benefit from systematic automation.

Streamlined Receiving Processes

When shipments arrive, workers scan incoming products directly into the system. Quantities update instantly, and any discrepancies between purchase orders and actual deliveries flag immediately for investigation. This immediate verification prevents inventory inaccuracies from compounding throughout the supply chain.

Accelerated Order Fulfillment

Pick lists generate automatically based on optimal warehouse routing. Workers follow efficient paths through storage areas, reducing travel time and increasing orders processed per hour. Real-time updates ensure pickers always receive accurate location information, even when inventory positions change throughout the day.

Selecting the Right Solution for Your Business

Automated inventory management Not all inventory systems suit every organization equally. Company size, industry requirements, growth projections, and existing technology infrastructure all influence which solution delivers the best value.

Small businesses may find cloud-based platforms with monthly subscription pricing most accessible. These solutions require minimal upfront investment and scale easily as operations expand. Larger enterprises often benefit from customizable platforms that integrate deeply with existing ERP systems and accommodate complex multi-location requirements.

Conclusion

Embracing automated inventory management positions growing businesses for sustainable success in competitive markets. Throughout this guide, we’ve explored how these systems deliver real-time visibility, intelligent reorder automation, and accurate demand forecasting that transforms supply chain operations entirely. The benefits extend beyond simple efficiency gains to include reduced costs, improved accuracy, and enhanced customer experiences. While implementation requires thoughtful planning and investment, organizations that commit to inventory optimization gain significant competitive advantages. Stock management solutions continue evolving, offering increasingly sophisticated capabilities for businesses ready to modernize their operations. Taking action today prepares your company for tomorrow’s challenges and opportunities in supply chain excellence.